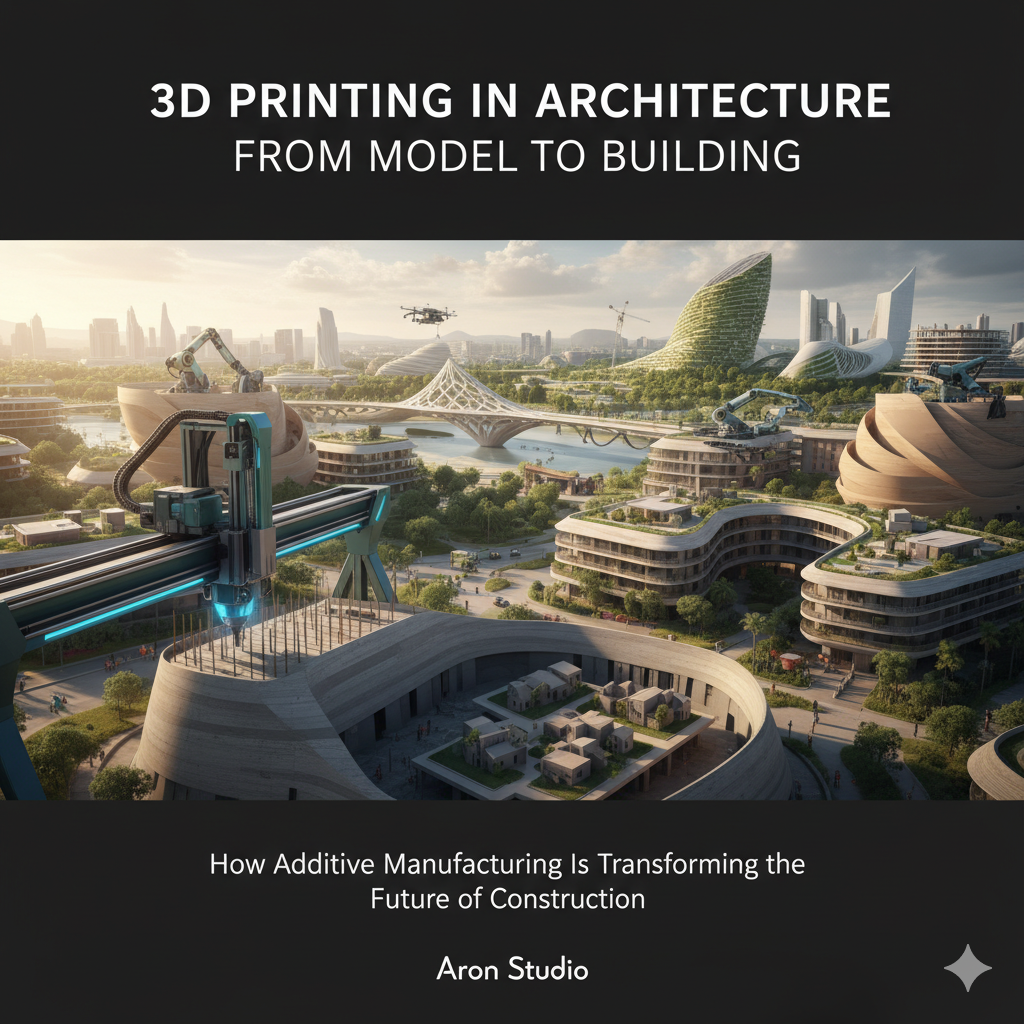

3D Printing in Architecture: From Model to Building – How Additive Manufacturing Is Transforming the Future of Construction

This article explores how 3D printing is reshaping contemporary architecture, moving from small-scale models to full-size structural components and even complete buildings. It explains the core principles of additive manufacturing, including material types, robotic extrusion methods, and digital workflow integration. Several international case studies highlight real applications in housing, infrastructure, and sustainable construction. The text also analyzes the cost benefits, such as material efficiency and reduced labor time, while acknowledging current limitations like regulatory barriers, material restrictions, and the need for hybrid construction methods. The article concludes by outlining the future potential of 3D-printed architecture, especially in sustainable building, mass customization, and automated construction technologies.

3D printing—known in the architecture industry as additive manufacturing—has rapidly evolved from an experimental tool into a practical construction method. Today, it enables architects and engineers to build everything from precise scale models to fully functional residential and public buildings. By combining digital design with automated construction, this technology is reshaping how we imagine, design, and build our environments.

This article explores how 3D printing works, global case studies, costs and advantages, limitations, and the future of this fast-growing construction method.

Why 3D Printing Matters in Architecture

The construction industry is currently facing three critical challenges:

labour shortages, rising construction costs, and the urgent need for sustainability.

3D printing offers a direct response to all three. With its ability to produce highly complex geometries, reduce material waste, and accelerate construction timelines, 3D printing has become one of the most influential technologies of the decade. For architecture firms, research institutions, and construction companies, additive manufacturing has opened the door to faster, more affordable, and more sustainable building methods.

How 3D Printing Technology Works in Architecture

Most architectural 3D printing systems use extrusion-based printing, where material is deposited layer by layer to create a full-scale structure.

Common Materials in Architectural 3D Printing

- Special 3D-print concrete or polymer-modified concrete

- Stabilised earth and clay mixtures

- Bio-composite materials

- Plastics (mainly for model-making)

- Fibre reinforcement for structural stability

The process usually begins directly from a BIM model or parametric design, creating a seamless link between digital design and physical construction.

Key Advantages of Additive Manufacturing

- No need for conventional formwork

- Freedom to build curved and organic geometries

- High speed and precision

- Reduced labour demand

- Digital automation and consistent quality

Global Case Studies of 3D-Printed Architecture

In the past decade, numerous large-scale projects have demonstrated the practical potential of architectural 3D printing.

Major International Examples

1. ICON Housing Projects – USA

Affordable, resilient homes printed in under 24 hours, supporting social housing and disaster-relief programmes.

2. Office of the Future – Dubai

One of the world’s first fully 3D-printed office buildings; a landmark for organic architectural forms.

3. 3D-Printed Pedestrian Bridge – Madrid, Spain

A concrete, parametric bridge by Acciona showing the structural capability of printed concrete.

4. NASA Mars Habitat Prototypes

Experimental construction using simulated Martian soil, preparing for future space habitation.

5. Winsun Printed Buildings – China

Multiple housing units printed within a single day, highlighting the technology’s construction speed.

These examples illustrate how 3D printing is steadily transitioning from experimental research into mainstream architectural practice.

Costs, Benefits, and Economic Impact

Benefits

- Up to 30% reduction in total construction costs

- Construction processes 3–5 times faster

- Up to 70% less material waste

- High design freedom for complex forms

- Reduced reliance on large labour teams

- Sustainable and energy-efficient construction

Costs and Financial Considerations

- Industrial printers cost €350,000–€600,000

- Specialised printing materials

- Transportation, calibration, and on-site setup

- Skilled technicians for printer operation

Depending on the region, project type, and materials, the total cost of construction can be 25–50% lower than traditional building methods.

Challenges and Limitations

Despite its rapid development, 3D printing still presents several challenges:

Technical Limitations

- Limited height and span depending on printer type

- Difficulty with complex structural connections

- High compressive strength but limited tensile performance

Regulatory Limitations

- Lack of standardised building codes

- Uncertainty in obtaining building permits

- Limited compatibility with conventional structural norms

Environmental and Climate-Related Concerns

- Need for improved thermal insulation

- Material performance varies in extreme climates

These challenges indicate that the technology is still maturing, but global development is progressing rapidly.

The Future of 3D Printing in Architecture

The next decade will bring major advancements in:

1. Integration with BIM and Parametric Workflows: Design-to-production processes will become fully automated.

2. Climate-responsive and Smart Materials: Next-generation printed materials will offer better strength and energy efficiency.

3. Hybrid Robotic Construction: Combination of 3D printing, robotic assembly, and reinforcement automation.

4. Affordable and Sustainable Housing: One of the most promising applications will be large-scale social housing.

5. Space Architecture and Extraterrestrial Construction: NASA and ESA are already testing 3D printing for off-planet construction.

In conclusion, 3D printing is redefining what architecture can become. By merging design innovation with digital fabrication, it offers a construction method that is faster, greener, and more flexible than anything seen before.

Although challenges remain—particularly regulatory and material-related—the global momentum behind additive manufacturing suggests that it will soon become a central pillar of sustainable, economical, and technologically advanced construction.