How Digital Fabrication and Parametric Design Are Shaping the Future of Architecture in Europe

Introduction: A Shift in How We Design and Build

The architectural profession is undergoing a fundamental transformation. In the past decade, the tools and technologies used by architects, designers, and builders have evolved rapidly — not just in how we visualize space, but how we produce it. One of the most significant changes comes from the integration of parametric design and digital fabrication into the everyday workflow of architectural studios across Europe.

Parametric design allows architects to create adaptive, intelligent systems that generate forms based on data, logic, and optimization. Digital fabrication enables the translation of those complex geometries into real-world structures through robotic arms, CNC machines, and 3D printers.

Together, these technologies are reshaping architecture — making it more precise, customized, efficient, and innovative. This article explores how parametric and digital fabrication are changing architectural design in Germany and Europe, what tools and techniques are leading this change, and how architecture studios like Aron Studio are integrating them into professional practice

What is Parametric Design?

Parametric design is a computational design approach that uses parameters — such as dimensions, environmental conditions, or performance goals — to drive the creation and variation of geometry.

Instead of drawing fixed forms, architects define rules and relationships between elements. These rules are processed by software like Grasshopper (for Rhino) or Dynamo (for Revit) to generate dynamic, responsive models.

Key Advantages:

- Highly flexible and adaptable designs

- Real-time feedback on performance metrics (sunlight, structure, airflow, etc.)

- Rapid iterations and form-finding

- Optimized use of materials and construction methods

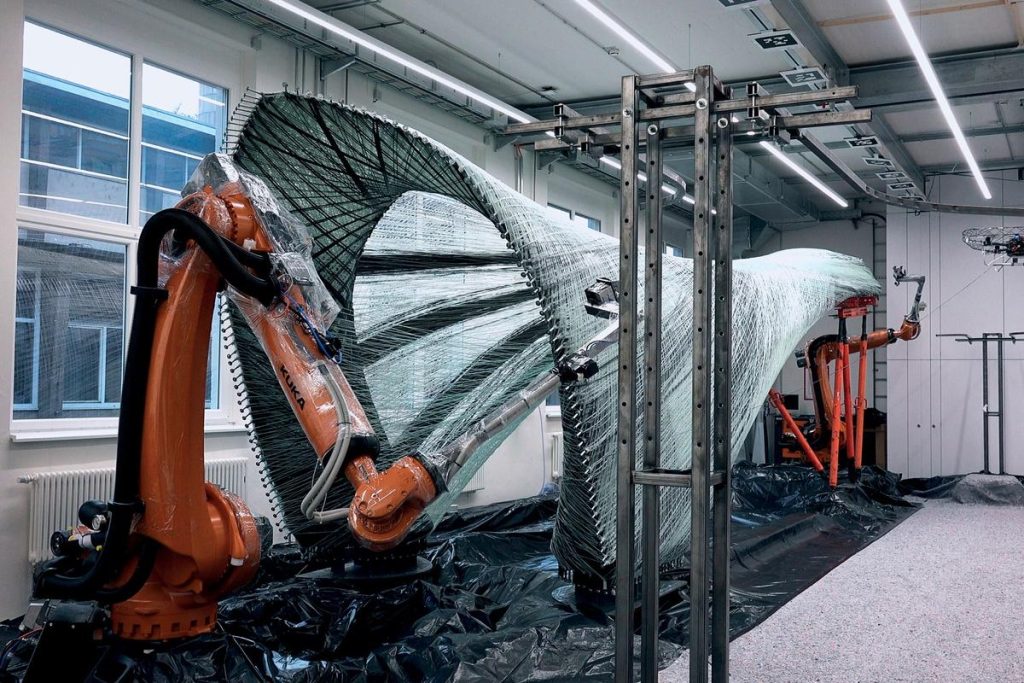

What is Digital Fabrication?

Digital fabrication refers to the use of computer-controlled machines to translate digital models into physical components or structures. The process includes several technologies:

| Technology | Application |

| CNC Milling | High-precision cutting of wood, metal, or stone |

| Robotic Arm Fabrication | Multi-axis fabrication for curved, complex geometries |

| 3D Printing | Additive manufacturing with plastic, resin, ceramic, or concrete |

| Laser Cutting | Clean, detailed cuts in sheet material |

| Ceramic 3D Printing | Creating functional or decorative ceramic forms |

Digital fabrication allows architects to go beyond the limits of conventional construction. Non-standard forms, once prohibitively expensive or impractical, are now feasible — and in many cases, cost-effective.

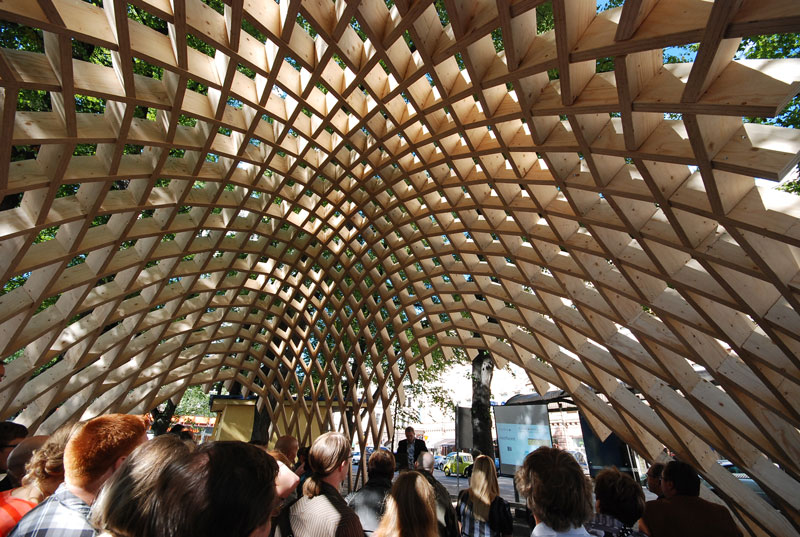

The Rise of Parametric Design in European Architecture

parametric-architecture.com

In Europe, especially in countries like Germany, Switzerland, the Netherlands, and the UK, parametric design is becoming an integral part of architectural education and practice.

Universities such as ICD (University of Stuttgart) and ETH Zurich have led research in adaptive structures, responsive envelopes, and robotic construction.

Examples of Parametric Architecture in Europe:

- ICD/ITKE Research Pavilions in Stuttgart

- The Twist Museum (Norway)

- The Edge Office Building (Amsterdam)

- Pavilion designs for Biennales and Expos

These projects show how data-driven design creates smarter, lighter, and more sustainable architecture.

Combining Parametric Design and Digital Fabrication

The real power of these technologies is unlocked when they are used together.

Let’s say you’re designing a geometric ceiling system with thousands of unique panels. Traditional workflows would make this almost impossible to fabricate. But with parametric design:

- The geometry can be generated based on acoustic performance

- The system can adjust based on lighting conditions and material behavior

- Files can be directly exported to CNC or 3D printing for fabrication

This connection from “design to production” is what makes the future of architecture so efficient.

Key Benefits for Architects and Clients

Whether you’re an architect, a developer, or a private client, these new tools bring real value:

1. Speed and Efficiency

Once set up, parametric systems can produce detailed alternatives and fabrication-ready files in a fraction of the time compared to manual methods.

2. Customization at Scale

It’s now possible to mass-produce customized elements, like panels or modular components, without increasing cost per unit.

3. Sustainability

Data-driven optimization ensures less material waste, smarter structural behavior, and more energy-efficient buildings.

4. Competitive Edge

Studios using digital fabrication can offer unique, precise, and faster solutions — gaining an edge in a competitive market.

How Aron Studio Leads This Transformation

At Aron Studio, based in Baden-Württemberg, Germany, we combine traditional architecture services with cutting-edge technologies in parametric design and digital fabrication.

As a registered architectural office and a team of professionals with deep expertise in both HOAI-compliant planning and advanced fabrication, we provide:

- Full architectural and interior design services

- BIM-based planning and permit applications

- Custom 3D-printed components

- CNC-cut and robotically milled elements

- Ceramic prototyping and product development

- Exhibition structures, public installations, and high-end furniture

We help clients turn bold, complex visions into reality — faster and more affordably than expected.

Real Applications

Here are some real-world applications of parametric + fabrication workflows we’re seeing today:

- Modular pavilions for exhibitions and museums

- 3D-printed façades with shading or ventilation properties

- Acoustic wall panels with organic shapes

- Customized furniture systems

- Public seating and interactive installations

- Prefabricated sculptural staircases or ceiling elements

These aren’t concepts. They’re being designed, fabricated, and installed now — across Europe.

Challenges to Consider

As with any emerging technology, there are challenges:

- Learning Curve: Software and workflows can be complex

- Coordination: Digital fabrication requires precise coordination with manufacturers

- Material Limits: Not all materials are ideal for all fabrication types

- Costs: Upfront costs for setup can be higher — but often balanced by time savings and flexibility

That’s why partnering with the right team — with design and production under one roof — is critical.

What’s Next for Architecture in Europe?

With increasing demands for sustainability, customization, and efficiency, the future of architecture in Europe lies in intelligent, integrated systems.

Studios that embrace parametric design and digital fabrication are not just keeping up — they are leading.

At Aron Studio, we believe this is not just a trend. It’s a new standard.

Ready to Build the Future?

Whether you’re planning a project, developing a product, or exploring experimental design — we invite you to discover how Aron Studio can support your vision.

📞 Let’s talk today.

🌐 www.aron-studio.de

📧 info@aron-studio.de